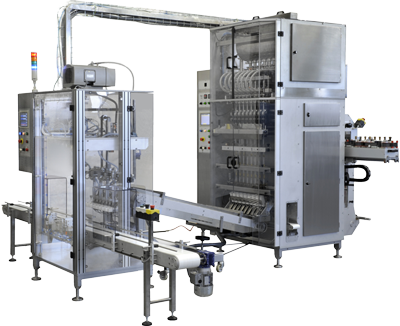

The multitube packaging machine forms, fills and seals tubular sachet sealed on 3 sides, called “sticks”, and pyramidal sachet, called “tetrahedrons”.

The Multitube packaging machines are made in two version:

• Multitube, with asynchronic motor;

• Multitube-s, which is controlled completely by Brushless servo-motors which provide accuracy of dosing and high precision of sealing.

The machines are made from stainless steel and anodized aluminium and are equipped with PLC and touch-screen to constantly monitor function and parameters to diagnose alarms and anomalies.

The good quality of materials of the machine and a cantilever sealing area allow the easy control, cleaning and handling of the machine.

The Multitube machines are able to pack any sort of product such as powders, granulates, liquids or pastes for various sectors of good like food, pharmaceutical, cosmetic and chemicals.

Depending of the product to be packed, the machine can be equipped with appropriate dosing unit or combination of dosing units.

In base of the stickpack bag width, the Multitube machine can be produced with output lanes ranging from 2 to 20 lines.

• Conveyor belt systems

• Stacking / systems for counting

Forming boxes •

• Forming Machines

• Devices for Packing Group

• Paletttizer

• Conveyor belt systems

• Stacking / systems for counting

Forming boxes •

• Forming Machines

• Devices for Packing Group

• Paletttizer

• Conveyor belt systems

• Stacking / systems for counting

Forming boxes •

• Forming Machines

• Devices for Packing Group

• Paletttizer

• Conveyor belt systems

• Stacking / systems for counting

Forming boxes •

• Forming Machines

• Devices for Packing Group

• Paletttizer

Processing of personal data is any process or set of procedures performed on personal data, whether automated or non-automated, such as collecting, recording, organizing, structuring, storing, adapting or modifying, finding, inspecting, using, detecting, transmitting, disseminating or posting otherwise available, harmonizing or combining, restricting, deleting or destroying.

The policy applies to all services of DORA-PAK d.o.o. which include personal data processing activities in which DORA-PAK d.o.o. controller in the sense of the General Data Protection Regulation (Regulation of the European Parliament and of the Council of 27 April 2016 on the protection of individuals with regard to the processing of personal data and on the free movement of such data available at: http://data.europa.eu/eli / reg / 2016/679 / oj